Ms. Jiang

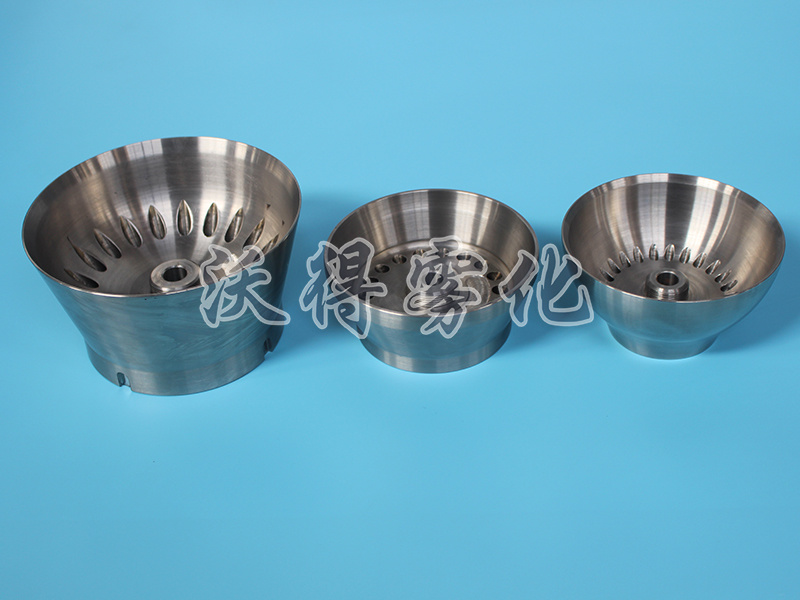

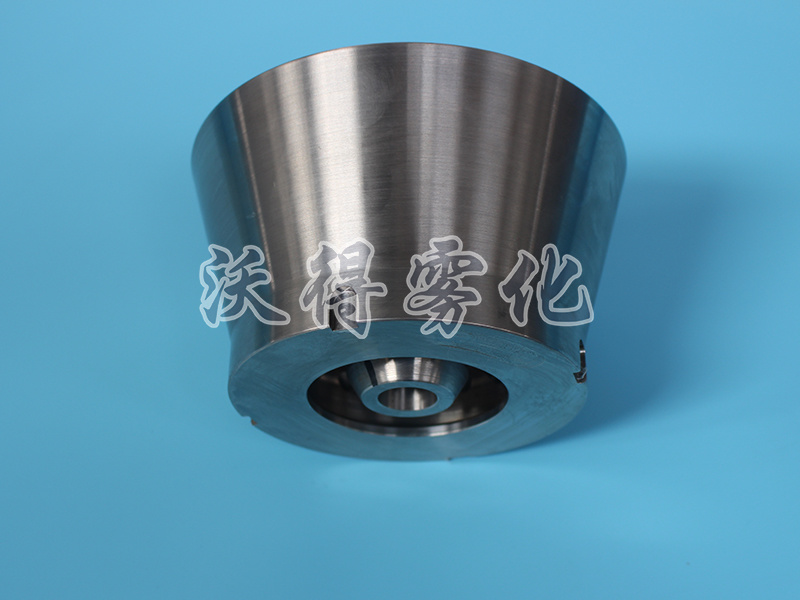

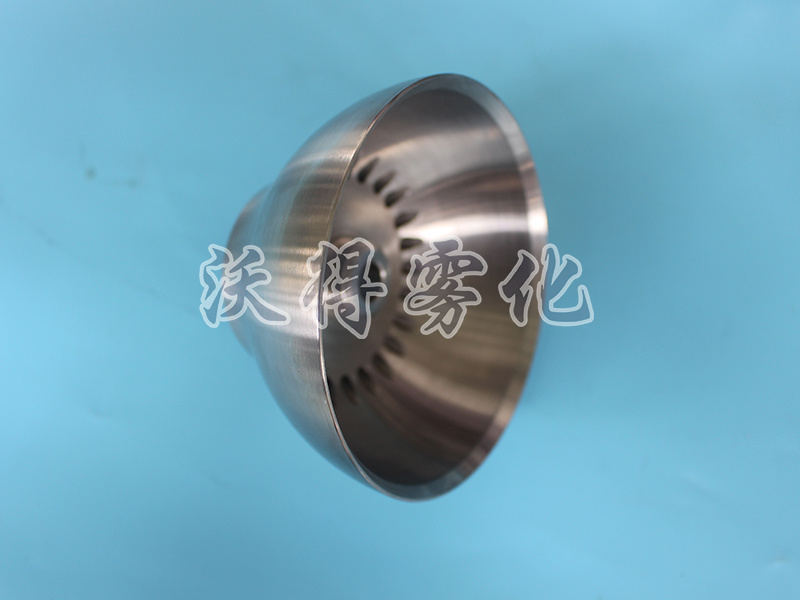

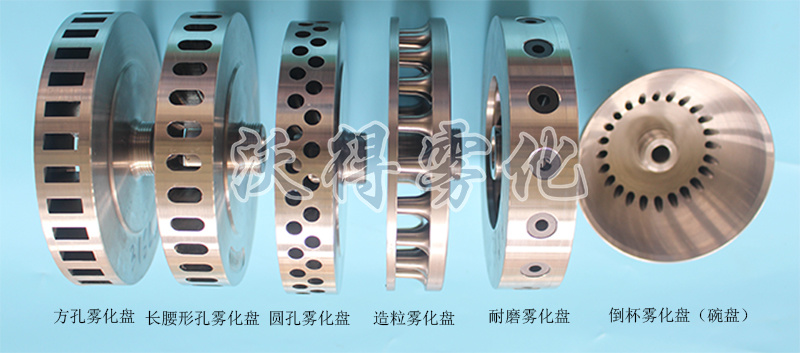

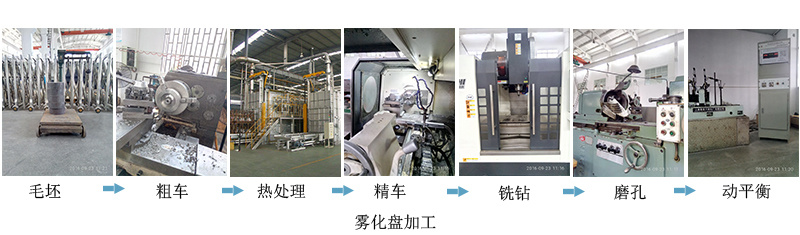

Leave a messageIt is shaped like an inverted bowl with a smooth surface and a sharp periphery. The feeding cavity is set at the center, and the liquid first falls on the liquid distribution plate, so that it flows evenly downward along the bowl-shaped body, and when it reaches the mouth of the bowl, the liquid is thrown out by centrifugal force to atomize, and this structure effectively reduces the phenomenon of liquid sticking to the wall in the tower, which greatly improves the output rate of dry powder. The inner hole of the atomization disk is ground by precision grinder, with high degree of finish, combined with the spindle, etc. Finally, it is calibrated by precision dynamic balancing instrument.

Tips: We can customize the atomization disc for different purposes according to customer needs, for particle size control, material flow increase, atomization disc wear resistance enhancement, etc.

Dynamic Balancer