Ms. Jiang

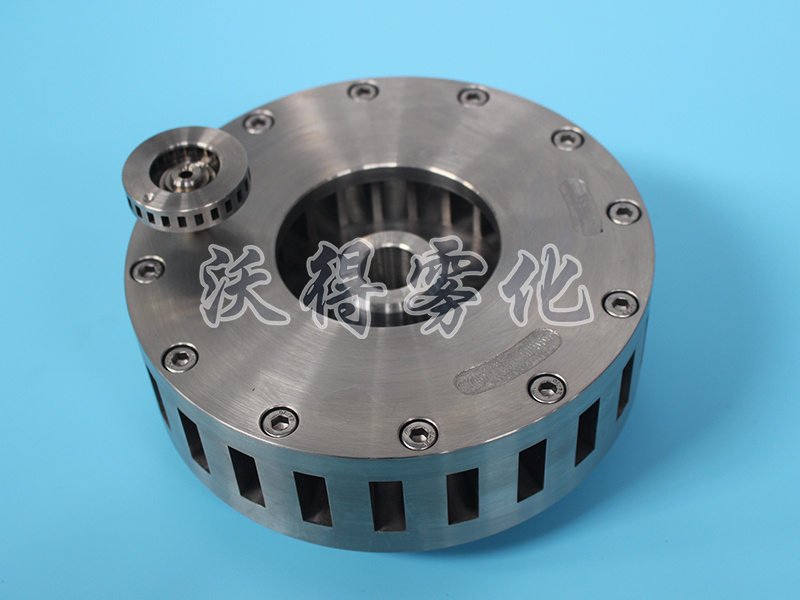

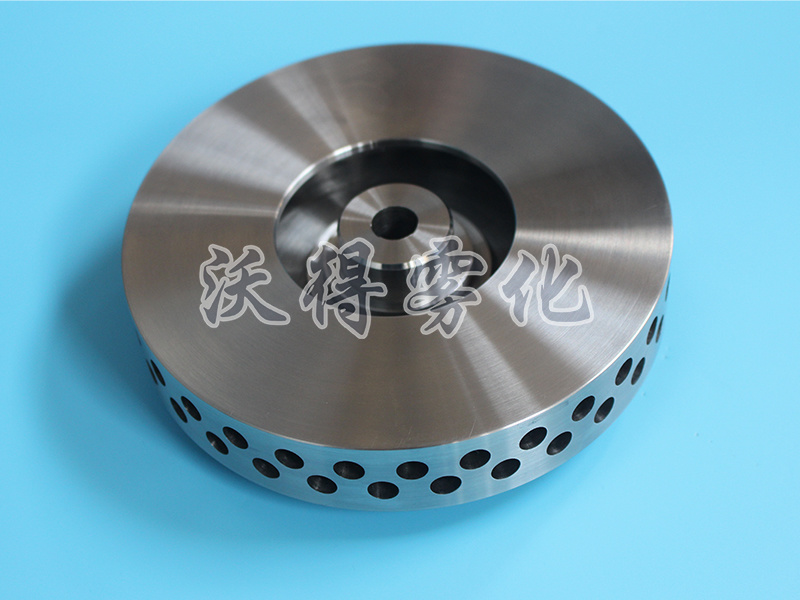

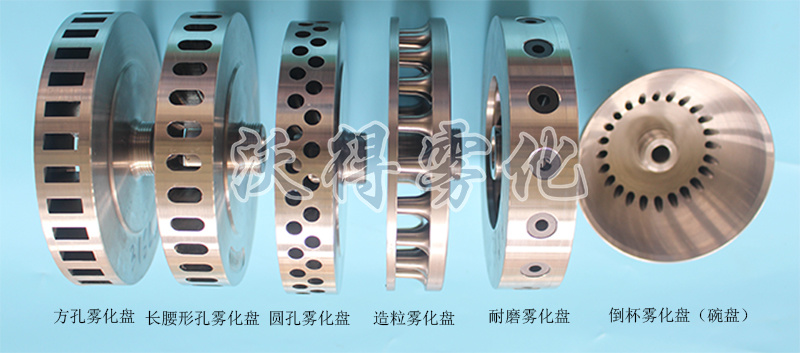

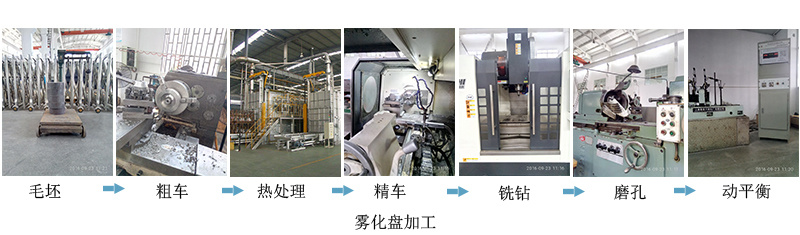

Leave a messageConventional Atomizing disc discharge holes are rectangular, waist-shaped, round, etc. It has the advantages of fast discharge speed, good atomization effect, thin spray liquid film, small atomized particles, etc. The main body of the atomizing disk is made of stainless steel such as 304, 316L, etc. For spraying other strong corrosive materials such as strong acid materials, titanium alloy and pure titanium materials can be used, and for high temperature and high corrosive environment, Hastelloy can be used. The outer diameter of the atomizing disk varies from Φ50-Φ300mm. The inner bore of the atomizing disc is ground by precision grinder, which has the characteristics of high finish and close combination with spindle, etc. Finally, it is calibrated by precision dynamic balancing instrument.

Tips: We can customize the atomization disc for different purposes according to customer needs, for particle size control, material flow increase, atomization disc wear resistance enhancement, etc.

Dynamic Balancer